Products

Conical Ribbon Mixer

Conical Ribbon Mixer consists of a transmission device, taper cylinder, outer ribbon mixer, inner reverse screw mixer and discharge valve. It is a new design for viscosity material. The material circles and rises under the operation of the outer ribbon mixer, while the inner reverse screw presses down the material along the shaft, which finishes the mixing. With a long force arm and weak impact force,this equipment is suitable for the mixing and reaction of highly adhesive liquids with viscidity under 200, 000cp, such as paint, coating material and adhesive. It is particularly useful for the mixing of non-Newton fluids containing a lot of solid elements.

View >>

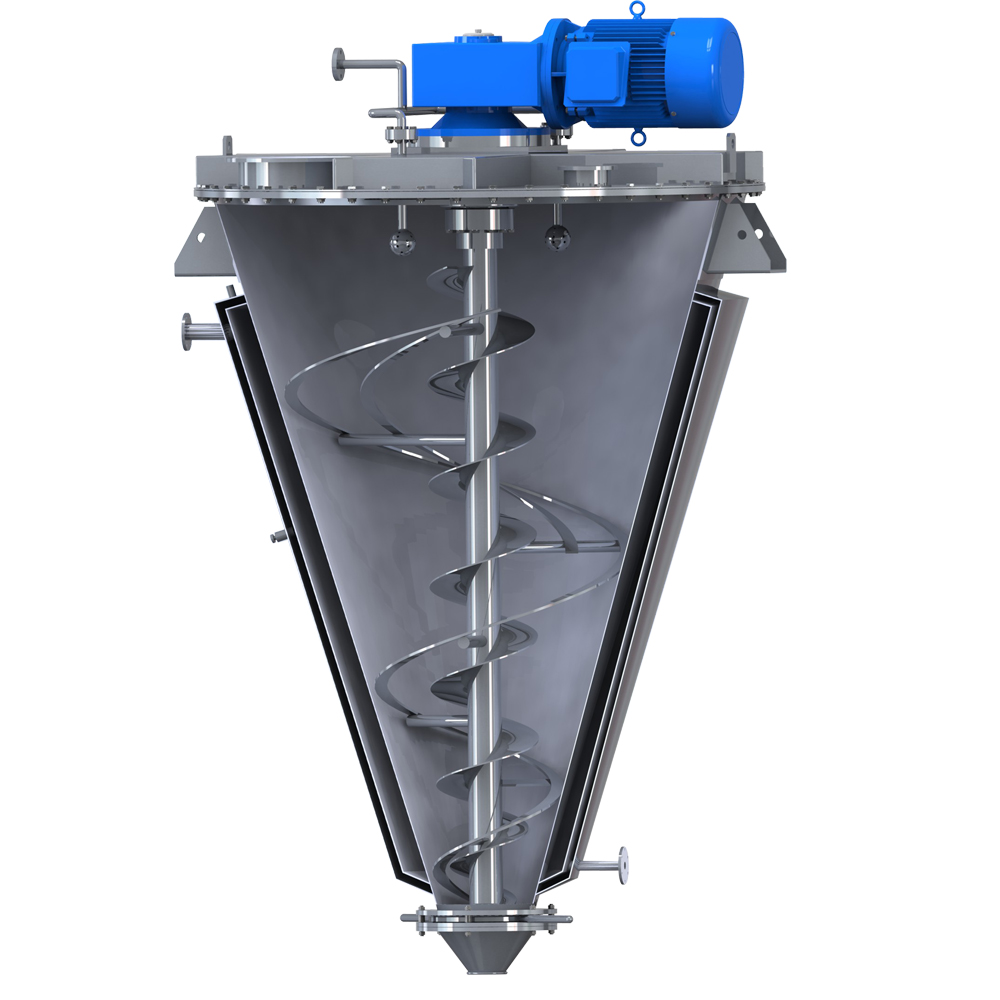

Conical Screw Mixer

This mixer is broadly applied for the solid-solid (powder to powder) and solid-liquid (powder to liquid) and liquid-liquid (liquid to liquid) mixings in food, pharmacy, chemical industry, fertilizer, oil field, oil refining, animal remedy, coating, pigment, dyestuff and assistant, metallurgy, smelting, fireproof material, mine, building material, battery, electronic plastic,fodder, cultivation, biological project, health product, ceramic, glass, new material, nuclear material etc. trades. This mixer is greatly suited with mixed materials, will produce no lamination and maceration phenomenon to the mixing combined with thermo-sensitive materials and holds a good suitability to the mixing of rough materials, fine grains and extra-fine powders etc. various grains, fibers or lamellate materials.

View >>

Double Shafts Paddle Mixer

Double Shafts Paddle Mixer is of a low energy consumption and a large loading coefficient, moves steadily, is in sealed operation, without pollution to the environment, and easily used, maintained and repaired. SYJW dual-axis paddle horizontal mixer (also called as: gravity-free grains mixer or dual-axis paddle mixer) is broadly applied for the material mixing process in chemical, agricultural chemicals, pharmacy, dyestuff, beverage, food additive etc. industries, including solid-solid (powder to powder) and solid-liquid (liquid sprayed powder) mixings and the mixing and drying operations under a vacuum state. The mixer features quick mixing,high mixing precision, non-produced segregation, warm mixing process, low energy consumption, large filling coefficient, steady movement, sealed operation, non-environment pollution, easy installation, use and repair.

View >>

Horizontal Ribbon Mixer

Orizontal ribbon mixer can be used for the materials mixing production in food, medicine, chemical plastic,dyestuff and cosmetic etc industries to mix solid-solid(powder and powder),solid-liquid(powder and liquid), especially, suit for mixing the materialadhesive or containing coherent powder articles and that powder articlesmaterial which is added with more liquid(or pasty material) and features aquick mixing speed, a high precision, non-blind mixing area, a great fillingcoefficient, stable movement, sealed operation, without pollution to theenvironment, quick and clear discharge without residue, easy to use andmaintenance.

View >>

Plough Mixer

Plough Mixer is a high speed mixer with high homogeneity. During the mixing process, the raw materials are transferred around the drum in a radial, lateral and longitudinal movement by the high speed plough shears and choppers. Moreover, the mixing time is short, especially for free flowing powders or granules. Liquid additive and Heating or Cooling is also applicable.

View >>