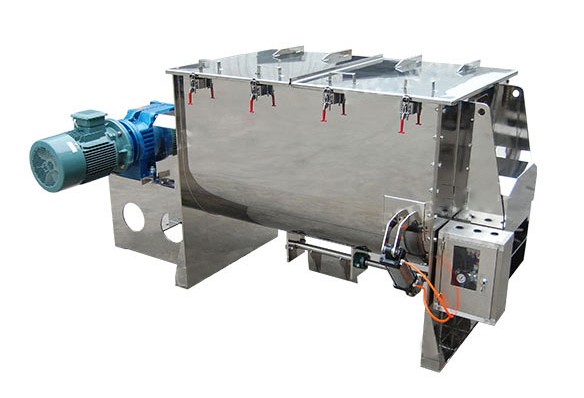

Horizontal Ribbon Mixer

Introduction

Orizontal ribbon mixer can be used for the materials mixing production in food, medicine, chemical plastic,dyestuff and cosmetic etc industries to mix solid-solid(powder and powder),solid-liquid(powder and liquid), especially, suit for mixing the materialadhesive or containing coherent powder articles and that powder articlesmaterial which is added with more liquid(or pasty material) and features aquick mixing speed, a high precision, non-blind mixing area, a great fillingcoefficient, stable movement, sealed operation, without pollution to theenvironment, quick and clear discharge without residue, easy to use andmaintenance.

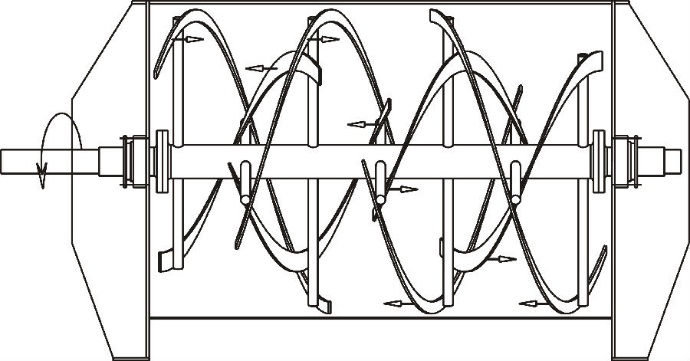

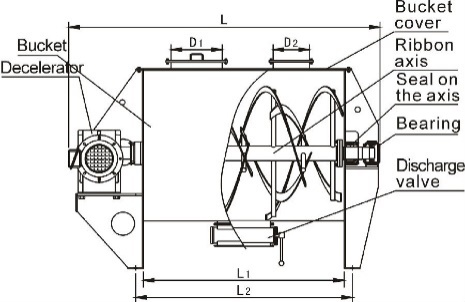

Working principle:

With the actuation of the directly linkdecelerator, the rotor moves in a fixed direction and , during its movement,the horizontal ribbon mixer pushedworking principle the material to move along with the axis and, on the other hand, throw the material to the front upper of the helicalribbon. The helical ribbon on the outside layer makes the material alwaysmoving towards the center of the barrel while the one on the inside layer makesthe material moving towards two ends from the center, thus two cycled ways offlowing are formed with the material, making it fully mixed in the repeatedflowing circulation.

Product introduction

1.Flexible material selection

Material can be carbon steel, manganese steel, ss304, 316L and 321; besides, different material can also be used in combination.

Material is different between the part contact with the raw material and the parts don’t contact with the raw material.

Surface treatment for stainless steel include sandblasting, wiredrawing, polishing, mirror polishing, all can be used in different parts of a mixer.

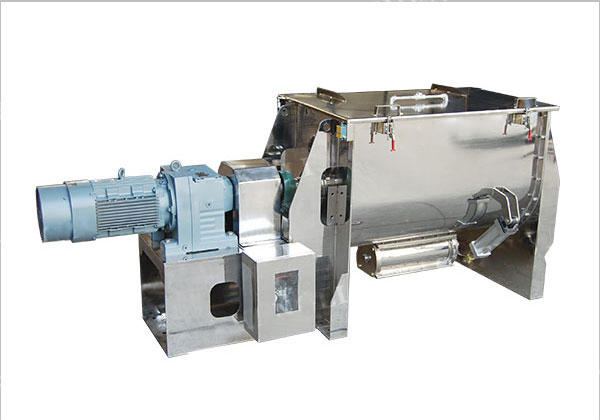

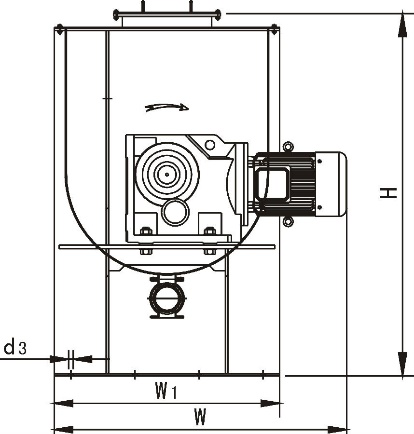

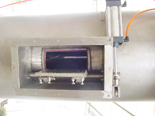

2.Reliable driven unit

The driven unit, power and output speed are varied according to different raw material, starting method, and processing.

Options for motor: general motors, explosion-proof motors, variable frequency motor, high efficiency and energy saving motor.

Commonly used reducers: R-series, K-series, and F-series gear box; cycloidal reducer, universal gear reducer, planetary gear reducer. Commonly motor-gearbox connection: direct connection, pulley connection, hydraulic coupler connection.

3.High efficiency mixing unit

Different main shaft agitators can be equipped according to the properties of raw materials.

Materials commonly mixed are: different kinds of powder to be mixed with each other, batches mixing for the same material, powder with a small quantity of liquid, liquid with some powder, like slurry, thickening or diluting slurry, granule with powder, granule with granule, or agglomerated material breaking and mixing, and cooling or heating.

The main shaft agitator could be: inner and outer ribbon, paddle and ribbon, disconnected ribbon, and shaver-shaped agitator.

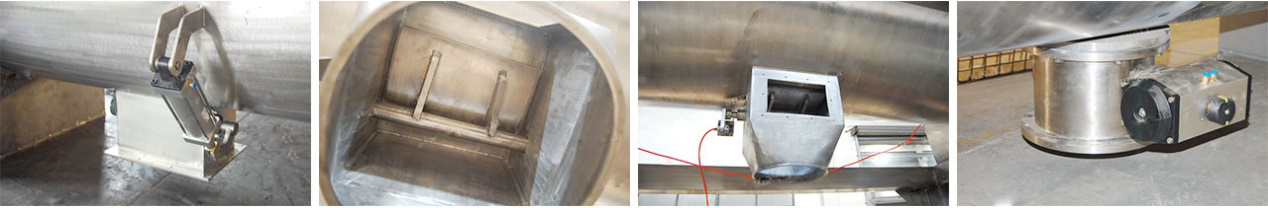

4.Excellent discharging unit

Standard valve for horizontal mixer is pneumatic planar flap valve. When close the valve, the planar flap match the mixing barrel perfectly, this makes no mixing dead zone and better mixing effect.

The drive types of valve are Manual, pneumatic, and electric.

Valves for consideration: powder spherical valve, cylinder valve, plum-blossom dislocation valve, butterfly valve, rotary valve etc.

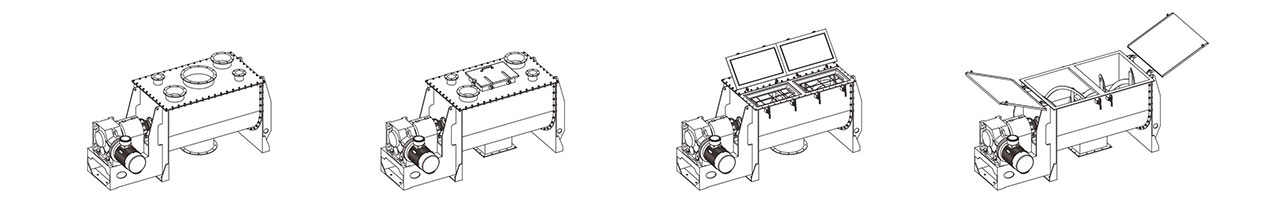

5.Various inlets

Various inlets on the top cover of the barrel can be designed according to different situations.

They can be used as man hole, cleaning door, feeding hole, vent, and dust colleting hole. The top cover can be designed as fully-opened lid for easy cleaning.

6.Powerful auxiliary components

Mixer is frequently equipped with many auxiliary components, like steam coil jacket, honeycomb pressure jacket, medium circulation jacket, sampling valve, high speed chopper, temperature sensor, weighing system, dust removal system and so on.

Different heat medium requires different jacket, it can be used for heating and cooling, while, the temperature should be within 250 Celsius degree.

If a small quantity of liquid is required during mixing, spraying or atomizing unit is necessary in order to mix the liquid evenly with the main ingredient. The liquid-adding system is basically composed by the three parts: pressure source, liquid storage pot and spraying nozzles.

Specification

Standard Features:

- Volume: 100-20000L

- Stainless Steel or Carbon Steel

- Ribbon agitator for center discharge

- Designed for normal temperature and normal atmospheric pressure tator for center discharge

- Feed Nozzle

- Dust Nozzle

- Manually operated or Pneumatic operated flap valve

- Packing Seal

- Safety limit switch on cleanout door

Optional Features:

- Carbon Steel, Stainless Steel 304, Stainless Steel 316L

- Continuous ribbon agitator, interrupted ribbon for higher density materials

- Internal pressure

- Sanitary type construction

- Flap valve, butterfly valve, slide gate valve, ball valve

- Horsepower to suit higher density materials

- Explosion-proof motors

- Controls such as variable frequency drives, motor starters and operator stations are available

- Spray nozzles for liquid introduction

- Jacket for heating or cooling

|

Model |

Mixing Volumne |

Speed (r/min) |

Motor Power |

Feed port (mm) |

Discharge Port (mm) |

Sizes(mm) |

Weight(kg) |

|

VZH-0.1m³ |

40L-60L |

76 |

3KW(4HP) |

1-Φ350 |

Φ100 |

1080(L) *758(W) *615(H) |

330 |

|

VZH -0.3m³ |

120L-180L |

66 |

4KW(5.5HP) |

1-Φ400 |

500*90 |

1550(L) *812(W) *1015(H) |

780 |

|

VZH -0.5m³ |

200L-300L |

66 |

5.5KW(7.5HP) |

1-Φ500 |

500*90 |

1675(L) *1142(W) *1300(H) |

955 |

|

VZH -1m³ |

400L-600L |

41 |

11KW (15HP) |

1-Φ500 |

500*90 |

1970(L) *1497(W) *1550(H) |

1400 |

|

|

|

|

|

1-Φ350 |

|

|

|

|

VZH -2m³ |

800L-1200L |

41 |

18.5KW (25HP) |

1-Φ500 |

500*90 |

2480(L) *1651(W) *1805(H) |

2500 |

|

|

|

|

|

1-Φ350 |

|

|

|

|

VZH -3m³ |

1200L-1800L |

33 |

22KW (30HP) |

1-Φ500 |

500*90 |

2880(L) *1896(W) *2055(H) |

3300 |

|

|

|

|

|

1-Φ350 |

|

|

|

|

VZH -4m³ |

1600L-2400L |

33 |

22KW (30HP) |

1-Φ500 |

500*90 |

3026(L) *1946(W) *2205(H) |

3600 |

|

|

|

|

|

1-Φ350 |

|

|

|

|

VZH -5m³ |

2000L-3000L |

26 |

30KW (41HP) |

1-Φ500 |

500*90 |

3518(L) *1945(W) *2205(H) |

4620 |

|

|

|

|

|

1-Φ350 |

|

|

|

|

VZH -6m³ |

2400L-3600L |

26 |

37KW (50HP) |

1-Φ500 |

500*90 |

3905(L) *1882(W) *2179(H) |

5300 |

|

|

|

|

|

2-Φ350 |

|

|

|

|

VZH -8m³ |

3200L-4800L |

26 |

45KW (61HP) |

1-Φ500 |

500*90 |

3978(L) *2160(W) *2516(H) |

6800 |

|

|

|

|

|

2-Φ350 |

|

|

|

|

VZH -10m³ |

4000L-6000L |

20 |

55KW/ (75HP) |

1-Φ500 |

500*90 |

4500(L) *2270(W) *2667(H) |

8900 |

|

|

|

|

|

2-Φ350 |

|

|

|

|

VZH -12m³ |

4800L-7200L |

20 |

55KW/ (75HP) |

1-Φ500 |

500*90 |

4486(L) *2466(W) *1305(H) |

9520 |

|

|

|

|

|

2-Φ350 |

|

|

|

|

VZH -15m³ |

6000L-9000L |

17 |

75KW (102HP) |

1-Φ500 |

500*200 |

5363(L) *2450(W) *3070(H) |

9950 |

|

|

|

|

|

2-Φ350 |

|

|

|

|

VZH -20m³ |

8000L-12000L |

17 |

75KW (102HP) |

1-Φ500 |

500*200 |

5670(L) *2650(W) *3497(H) |

11140 |

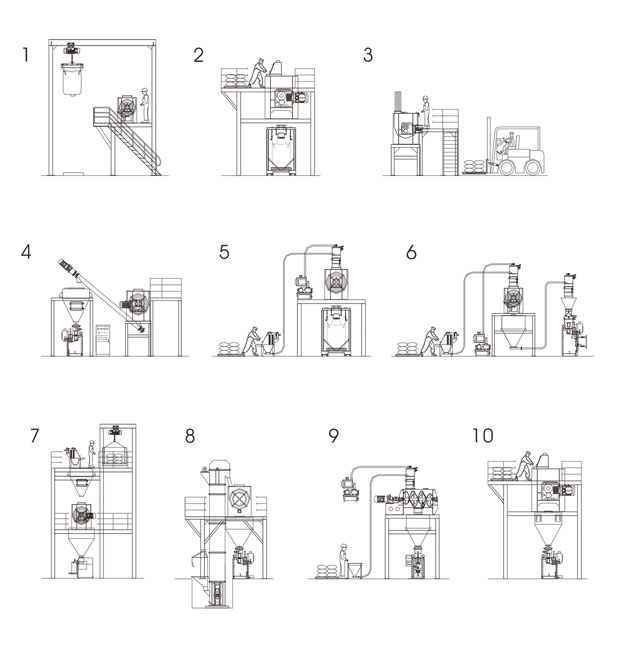

Accessory project

Configuration 1: using crane to hang bigbag material and feeding the mixer with the help of dust collector.

Configuration 2: mufti-level platform, manual undo the bag, mixing and packing with a bulk bag packer.

Configuration 3: simple mixer frame, feed a discharge directly with the help of a folk lift.

Configuration 4: using manual feeding platform, after mixing, screw conveyor send the material to the production silo, a packer under it.

Configuration 5: using vacuum feeder, load the material on the ground, after mixing, pack with a bulk-bag packer.

Configuration 6: multi-stage vacuum feeder, store it after mixing, then packing.

Configuration 7: multi-level operation platform, levator sending to material silo, mixing, storage, and then packing. Tower structure.

Configuration 8: bulket elevator feeding, mixing, storage, and packing.

Configuration 9: vacuum feeding, mixing, storage, packing.

Configuration 10: Manual feeding, mixing, storage, packing.

Common supporting equipments.

Download

Matching parts

A、Drive Advantages

Standard form coning helix mixer machine have two churn helix, Practical applies to in according to equipment specification size can adopt single (A long helix) , Double (Length each 1 incorrect states helix) , Three (Two short a long symmetrically disposal) Roots helix; Theoretically churns helix more many, Mixes effect more good.

B、U-Shape cylinder

Can tube of extraneous increase nip set of at mixer machine, Passes to nip set of in infuse into leng Re carrier come accomplish to materiel ‘s cool off or calefaction; Cools off ordinary pump enter industry use water, Heatings can go to enter steam or electric heating conduct heat oil.

C、Disconnecting type Spiral Belt

Go to enter spray liquid tube at mixer machine countershaft position, Connects fog melt nozzle, Can accomplish plus liquid mix; Passes choose specific material quality, Can join sour, Alkaline liquid materical proceeding powder liquid mix.

D、Discharging Mode

Tube of lids can make into dome, At decreases remain convenient for clean up ‘s meantime, Can enhance mixer machine a tube of body partial endure press intension, At needs mixer machine tube of body endure press time many adopt this enactment.

E、Cooling and heating

Can will mixer machine tube of body make into owe press storehouse at be specific craft in, Use flexible hose will liquidity good dry materiel suck enter mix storehouse proceeding mix, Can avoid materiel feed in raw material ‘s remain and pollution in tache.

F、Main Shaft Airproof

Standard form equipment ordinary adopts plum blossom Chuang” Makes malposition valve ” , Paste equal to tightness bottom this valve and long helix, Effective decreases mix dead angle, Drive form have manual gentle move can select; According to consumer need, Also can plus install reed valve, Ball valve, Starlike unloads glassware, Side comes out materical.